ADI

Austempered ductile iron

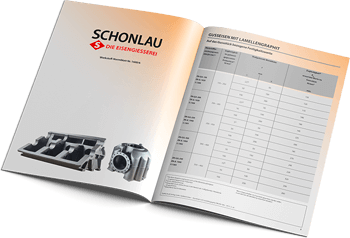

We produce compacted graphite iron in the following grade:

- EN-GJS-800-10 (5.3400)

- EN-GJS-900-8 (5.3402)

- EN-GJS-1050-6 (5.3403)

- EN-GJS-1200-3 (5.3404)

- EN-GJS-1400-1 (5.3405)

ADI is used for many products

- Gears

- Crankshafts

- Knee lever

- Rope drums

- Flange gear rims

- Planet carrier

ADI is characterised by a very favourable combination of tensile strength and elongation with very good abration resistance. On the basis of nodular graphite cast iron by a multi-level thermal treatment a definite micro-structural transformation is reached. Bainitic cast iron with nodular graphite (Austempered Ductile Iron = ADI) develops.

The price of ADI is considerable lower than of steel. Saving potentials already result from the production process in opposite to a steelwork or a forged steelwork part. With comparable mechanical properties, ADI possesses a lower specific weight than steel.

The dynamic characteristics of ADI are unbeatable (also after several million numbers of stress cycles). ADI parts work more silent and the abration resistance remains unequalled – opposite to conventionally steelwork parts.

The structure of bainitic cast iron is a mixture of acicular-shaped ferrite and carbon-enriched austenite (photo right). This structure is decisive for the steely characteristics of ADI.

Do you have any questions aboutADI?