Technical mentoring

We support you in the decision for a type of construction, the selection of the material, the pourable component construction and during the development with casting and solidification simulations.

On the photo you can see our colleagues in the technical office Jochen Lira und Thomas Veckenstedt

Transformation weldment / casting Construction units – poured or welded?

Our technical office develops a value analysis for your project. Convince yourself of the substantial cost savings which can be achieved, if welded are replaced by poured construction units. All-important is to get in contact as early as possible. The biggest chances are provided in the early stage of development. If design engineer and and casters work hand in hand at that time, compiled solutions, which fullfill the targets of both sides can be found. For a successful development partnership our competent foundry engineers are on your side.

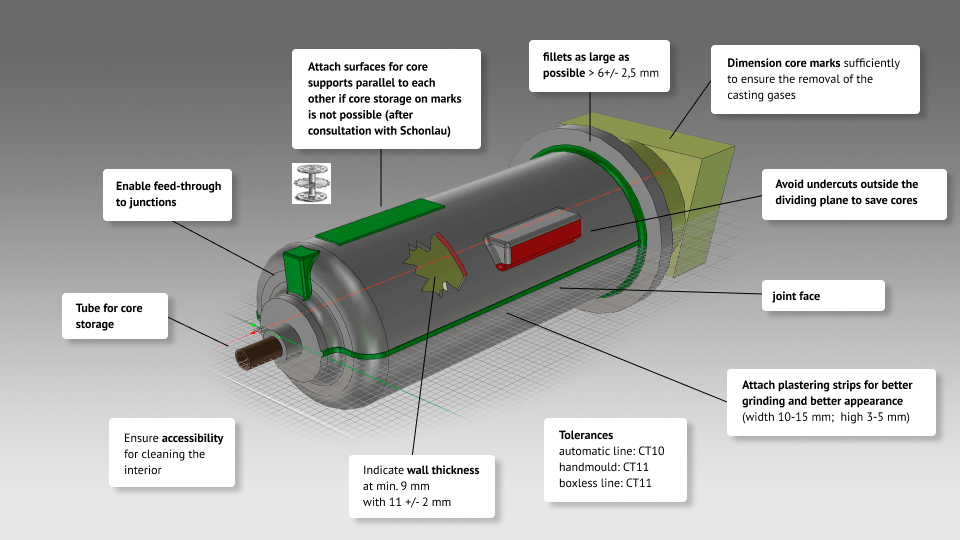

Construction mentoring

How do I design appropriate to casting?

The key to the optimal construction unit lies in co-operation. Find your competent development partner! We clear the way for an economic and appropriate to casting design. Avoid thereby constructional defects in an early state of development. By concert technical knowledge we exert influence on the final construction in time. Logistic advantages and above all economical production – we design appropriate to casting consolidated! Our technical office offers detailed information material to our customers. We would help you with your decisions by giving you technical know how in our technical designer conferences, which are arranged for our customers by our competent foundry engineers and matched to the special needs of your house.

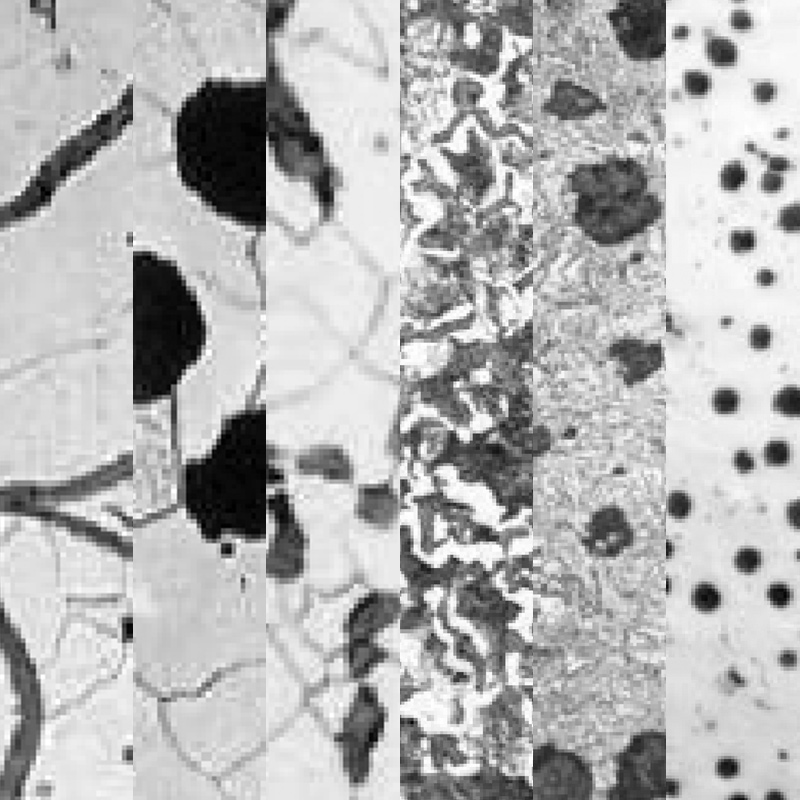

Material mentoring

Which material is the right one?

Iron casting offers a multiplicity of capabilities to you. In the majority of cases – depending on stress of the construction unit – compositions of several metals are concerned. Define your requirements like: Surface hardness, resistance, ductility, abration resistance, electrical conductivity, ability for the absorption of oscillations and corrosion resistance. As specified weldability and good machining characteristics, the surface finish plays an important role to the material selection. Of course also weight, size and form of the construction unit have to be considered. Just communicate your aims in an early state of development! We will find the optimal material for your construction unit – a successful development partnership saves costs, avoids failures and estabishes free space!

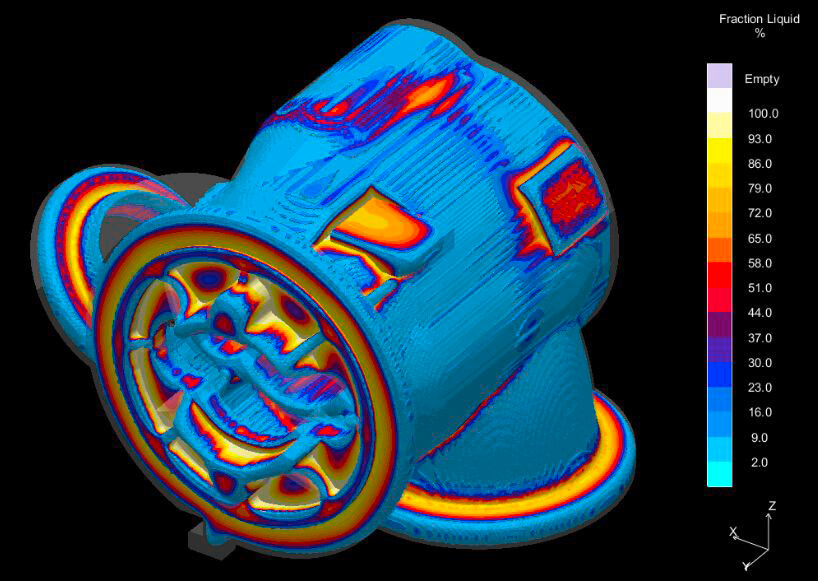

Casting and solidification simulation

Which advantages does the casting and solidification simulation offer?

The variety of the materials and design possibilities in the casting trade recovers likewise many advantages such as risks. The fabrication of the castings can be simulated parallel to the construction today.

A computer simulation allows to calculate both the mould filling and the solidification rate of the casting – close-to-reality. Potentitial failures can be avoided at the screen and problem zones inside casting can be determined. Construction and material are optimized by modification. Manufacturing methods like rapid prototyping permit a definit reduction of the process times.

Before building the first sample please send your 3-D-engineering-data so that potential failures can be minimized in the development phase.

We are there for you.