Quality assurance

high quality raw materials and continuous quality inspection

Basis for the high-quality Schonlau foundry products is the comprehensive quality assurance in our house. In connection with the use of high-quality raw materials and the constant quality inspection we ensure the permanent and reproducible adherence of all demanded analyses and casting temperatures. By means of process control, solidification simulation, plastic material analyses and metallographic analyses we realize the consistent protection of all quality relevant data.

Test equipment

To fullfill the requirements of the legislator and the high requirements of our customers, our quality assurance considers the following test equipments in our house:

- molding sands testing

- spectrographic and thermal analysis

- metallographic laboratory

- magnetic crack/particle detection/inspection

- dye penetrant technique

- ultrasonic testing

- tensile/tension test

- notched-bar impact test

- Brinell hardness test

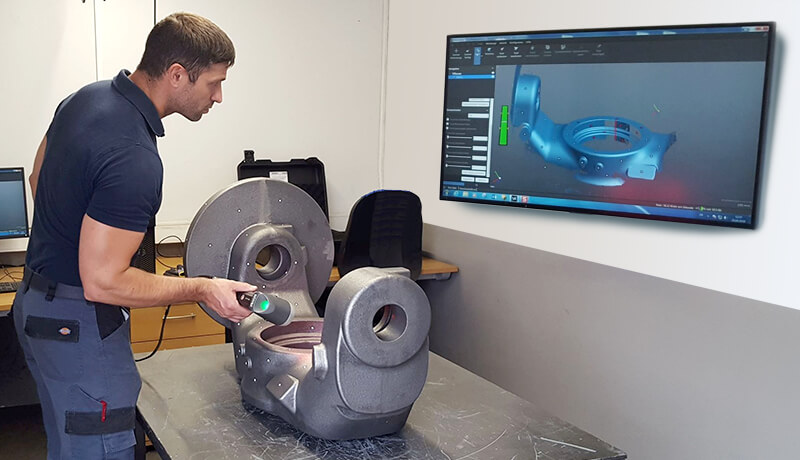

- part surveying

In close co-operation with bdguss and IFG extensive external quality audits are accomplished regularly.

3D scan in the Schonlau plant Measuring room

Certificates and licenses

The SCHONLAU plants are regularly certificated by the DIN EN ISO 9001.

We are there for you.